In a standard domestic hot water system, a single hot water supply leaves the tank and branches of to each fixture around the home, ending at the most distant. In larger homes it may take 1-2 minutes before any heated water arrives at the fixture and the line is left full of hot water, only to cool when the faucet is closed again. Hot water recirculation is used to reduce wait times at remote fixtures, thereby reducing water usage and possibly energy costs.

In a standard domestic hot water system, a single hot water supply leaves the tank and branches of to each fixture around the home, ending at the most distant. In larger homes it may take 1-2 minutes before any heated water arrives at the fixture and the line is left full of hot water, only to cool when the faucet is closed again. Hot water recirculation is used to reduce wait times at remote fixtures, thereby reducing water usage and possibly energy costs.

Most often found in commercial and industrial water distribution systems; hot water recirculation may also be a consideration for a residential system as well. Installing a hot water recirculation line is quite simple and relatively low cost but is most practical when planned into the design rather than a retrofit; as some systems, such as a home run system don’t lend themselves well to recirculation. There are two types of hot water recirculation used in residential homes, which are: Gravity recirculation and Forced recirculation.

- Gravity hot water recirculation

- Forced hot water recirculation

- Gravity loop installation

- Forced loop installation

Gravity Hot Water Recirculation

Gravity hot water recirculation works on the basic physical principal that heated water weighs less per unit of volume than cold water. When a return line is connected to the most distant fixture back to the water heater, a convection current will begin as the hot water rises from the tank into the supply line; the water that is already in the line begins to cool and sinks back to the tank through the return line creating a slow moving cycle.

With gravity being the driving factor in this type of system, the majority of the hot water distribution must be higher than the water heater. Houses with roof top heaters or those built on slab will require a circulator pump.

Since a gravity system only requires pipe and fittings to install, it is the cheapest of the two methods for recirculating hot water; however, its not the most energy efficient. To allow the water to circulate, the piping cannot be insulated, which means there will be a constant heat loss radiating from the pipe.

Installing a Gravity Recirculation loop

In a standard hot water distribution system the hot water leaves the tank and travels to the most distant fixture with branches coming of the main line (trunk) feeding each fixture. To install a simple gravity return system you will need to cut the supply pipe as close as possible to the end of the run and install a tee fitting to make a loop back to the tank.

If there is more than one main branch from the water heater you should install other return loops from those branches and connect them to the main return loop. Balancing valves (globe valves) should be used in this situation to prevent the heated water from travelling the path of least resistance. Balancing valves are installed just before the loop connects to the main return line. It will take some time to balance the system for optimal performance, so have some patience. If one section is getting more hot water than another, just partially close the hotter section’s balancing valve to force more of the heated water though the other section(s).

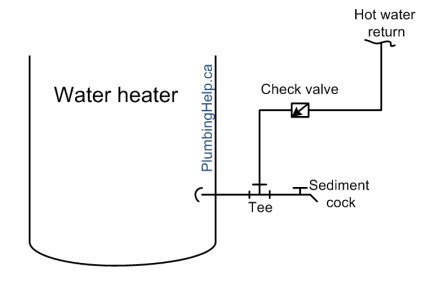

The return line needs to be installed so that it only goes horizontal and down or a heat trap could be created that would hinder the circulation. The return should be connected to the drain outlet of the water heater with a few fittings (Galvanized nipple, threaded brass tee and a sediment faucet) as seen in the image below.

Considerations for installing gravity hot water recirculation:

- This system is only practical when the water heater is located below most of the distribution piping. Houses with rooftop units or on slab construction or will require a circulator pump.

- Piping should not be insulated as the drop in temperature is what fuels the movement of water.

- A check valve is required to prevent cold water from short circuiting though the return line.

Forced Hot Water Recirculation

A forced hot water recirculation loop uses an electric inline circulator pump to push the heated water though the system, either continuously or at set intervals. Using a pump to circulate the water provides the greatest versatility in system design and has many benefits over a gravity loop because it doesn’t rely on the location of the tank, and the hot water lines can be insulated to reduce radiant heat loss.

A forced hot water recirculation loop uses an electric inline circulator pump to push the heated water though the system, either continuously or at set intervals. Using a pump to circulate the water provides the greatest versatility in system design and has many benefits over a gravity loop because it doesn’t rely on the location of the tank, and the hot water lines can be insulated to reduce radiant heat loss.

Some manufactures have developed “intelligent” domestic hot water recirculation pumps that include temperature sensors, timers and flow checks. These circulators pumps have further energy savings by only operating when required or at specific times when demand for hot water would be expected.

Installing a Forced Hot Water Recirculation Loop

Creating a forced hot water recirculation loop starts at the end of each hot water distribution branch, where a connection is made to return the piping back to the tank, connecting with other branches as it makes it’s way back. Using globes valves on the return lines from individual branches is necessary to balance the flow of heated water though the system.

Creating a forced hot water recirculation loop starts at the end of each hot water distribution branch, where a connection is made to return the piping back to the tank, connecting with other branches as it makes it’s way back. Using globes valves on the return lines from individual branches is necessary to balance the flow of heated water though the system.

All of the supply and return lines should be insulated which means you will have to hang the pipe instead of surface mounting it; such as along a joist.

The connection for the return loop can enter the tank either at the bottom; though the drain outlet, or be connected to the cold water supply. To prevent cross connections between the cold and hot lines, check valves must be installed on the cold water supply and the return line. An expansion tank must also be installed because the check valves create a closed system.

The circulator pump can be installed at the tank on the hot water supply or the return line, unless the pump manufacturer recommends a specific location.

The electrical connection to the pump typically comes prewired with a standard 110V (3 prong) plug but some models will require you to wire the connection independantly. See the installation instructions for your model.