Plumbers working in the commercial field may be called upon to install or service medical gas systems and distribution lines. Medical gas pipes are installed in numerous health care facilities for life saving equipment and care must be taken to insure 100% compliance with the code, for obvious reasons. In this article you will learn the proper materials and installation methods for medical gas piping.

Plumbers working in the commercial field may be called upon to install or service medical gas systems and distribution lines. Medical gas pipes are installed in numerous health care facilities for life saving equipment and care must be taken to insure 100% compliance with the code, for obvious reasons. In this article you will learn the proper materials and installation methods for medical gas piping.

This information is not to be considered valid unless cross-referenced against your local code.

Types Of Medical Gas Systems

Depending on the code for your area(Canada – CAN/CSA-Z305.1-92), the following non-flammable medical gasses may be covered:

- Oxygen (O2)

- Nitrogen (N2)

- Nitrous oxide (N2O)

- Medical air

- Medical vacuum

- Cryogenic liquids

- Less common gasses used are:

- Carbon dioxide (CO2)

- Helium (He)

- Ethylene (C2H4)

Medical Gas Acceptable Materials

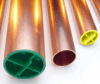

Piping – The only acceptable piping for the distribution of medical gas is seamless type “K” or “L” copper that is manufactured to the ASTM standard B819. Hard temper copper; size 1/2″ or larger, is used for all installations; however, soft copper may be permitted underground to reduce joints.

Medical gas copper pipe and tube will have blue or green markings specifying that it’s for medical gas (IE: TYPE K MED ASTM B819).

To protect from dirt and debris medical gas pipe will be shipped and stored with protective caps placed over the ends. Any contamination; such as oil, could cause spontaneous combustion when exposed to pure oxygen.

Valves and fittings – Any fitting designed for medical gas must meet the applicable standards for your region(Canada – CAN/CSA-Z305.1-92). Fittings must be capable of temperatures required for brazing if not threaded.

Threaded fittings are only to be used in accessible locations for testing/inspection and only to connect devices that cannot be brazed.

Installation Methods

Joints made in copper supplies for medical gas are made with silver braze that do not require flux. Flux may be used to make joints on dissimilar metals only(copper-brass). Protection from scale on the inside of the pipe; caused by brazing, requires a constant low flow of inert gas(nitrogen) while making any brazed joints. Installers must also keep any contaminants from entering the piping during the installation.

Threaded joints are made with approved joint compounds rated for medical use and must not contain oil if used on oxygen systems. Application of joint sealant is made to the male threads only, keeping the first three threads bare to prevent any compound from squeezing into the pipe.

Supports for medical gas piping is attained in the same manner as normal trade practice, but with added care in regards to the protection of pipes from physical harm. Medical gas pipe is hung independently from other piping(IE: don’t hang an oxygen line from a sprinkler line).

Pipe size Horizontal spacing(M) Vertical spacing(M) 1/2″ 1.8 1.8 3/4″ 2.4 1.8 1″ 2.4 2.4 1″-2″ 3.0 2.4 Over 2″ 3.0″ 3.0″

Identification Medical Gas Piping

Medical gas piping must be clearly identified using non removable stickers that are color coded according to the gas. Colors are standardized according to the code provisions in your area and should be spaced along the pipe, no more than 6m apart and also at every valve, at each access door and at each service connection.

Testing Medical Gas Pipe

Few installations a tradesperson will make could cause immediate loss of life if done improperly, hence the need to stringently test various aspects of medical gas piping installations. Inspectors will also randomly choose fittings to cut out and inspect the joints for scale and depth of penetration in the joint.

The following tests must be completed before putting the system into service:

- Pressure testing

- Cross connection test

- Concentration test

- Contaminant test

- Flow test