A mixing valve; also known as a tempering valve, is a mechanical thermostatic valve designed to control the water temperature output through the valve. Many areas require thermostatic mixing valves be installed on the domestic hot water supply; by code, for the protection of the residents.

A mixing valve; also known as a tempering valve, is a mechanical thermostatic valve designed to control the water temperature output through the valve. Many areas require thermostatic mixing valves be installed on the domestic hot water supply; by code, for the protection of the residents.

Why Do I Need A Mixing Valve

- May be required by code in your area.

- To protect your family and guests from scalding water burns and thermal shock. Every year numerous people (mostly children) are seriously injured by residential hot water that is set to high or improperly protected from pressure change.

- To protect the health of your family from water born diseases. The maximum water temperature at any fixture in your home is 120F or 49C (except a dishwasher), which is very close to the ideal conditions for Legionella Bacteria (Legionnaires disease). The way to prevent your water from becoming contaminated is keep the water heater set at 60C, killing the bacteria, and use a mixing valve to lower the supply water temperature.

How Do Mixing Valves Work

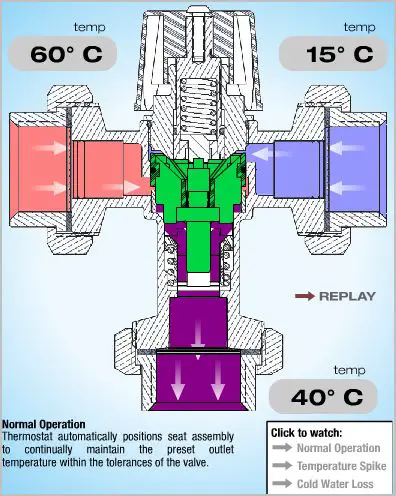

A thermostatic mixing valve operates by sensing the temperature of the blended water and adjusting the seat in the mixing chamber accordingly. If the cold supply water suddenly drops in pressure the seat will close, limiting the amount of hot water allowed to pass through.

Types of mixing valves

-

Source of supply – Residential, commercial, industrial uses for tempering entire hot water distribution systems.

Source of supply – Residential, commercial, industrial uses for tempering entire hot water distribution systems.

-

Point of use – residential, commercial and industrial uses, easily installed between the fixture supplies.

Point of use – residential, commercial and industrial uses, easily installed between the fixture supplies.

Temperature actuated flow reduction valve – Immediately closes in the event of a lose of cold water protecting you from being scalded. Used primarily to control the high limit water temperature of showers.

Temperature actuated flow reduction valve – Immediately closes in the event of a lose of cold water protecting you from being scalded. Used primarily to control the high limit water temperature of showers.

-

Tempering valve – Blends cold and hot water to extend the hot water capacity of residential water heaters and boiler coils.

Tempering valve – Blends cold and hot water to extend the hot water capacity of residential water heaters and boiler coils.

Pictures used with permission from Watts.com